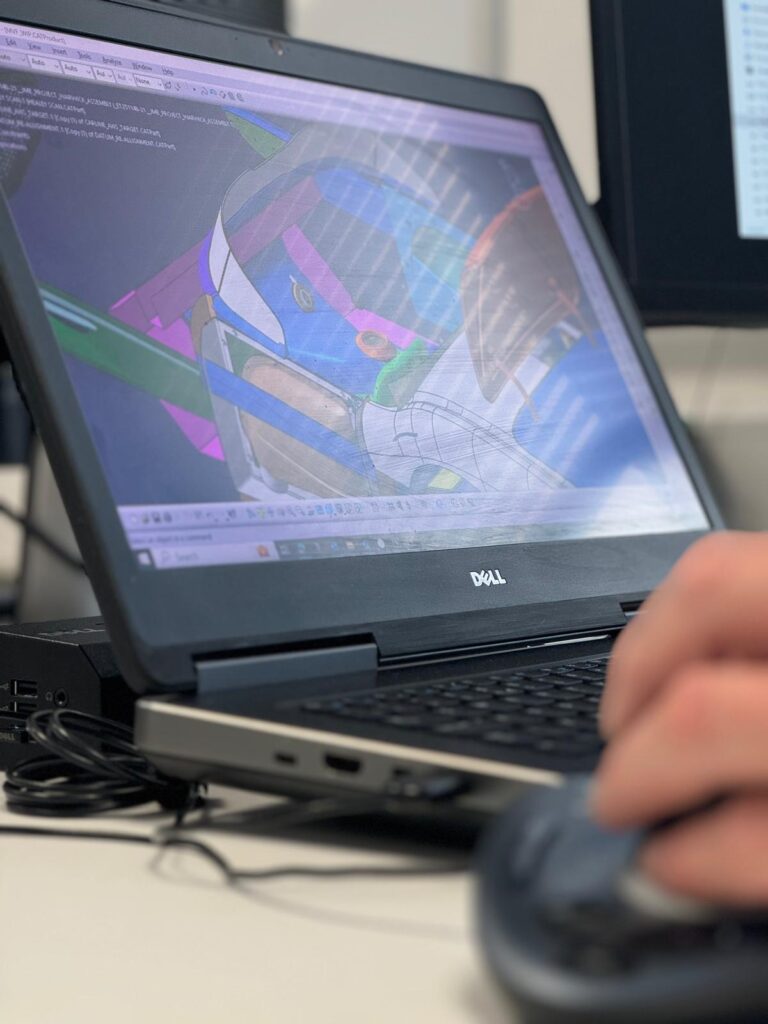

Taking our clients visualisations and turning them into a reality begins with our highly skilled, specialist CAD Design Team, supporting a variety of projects from beginning to end.

What is CAD?

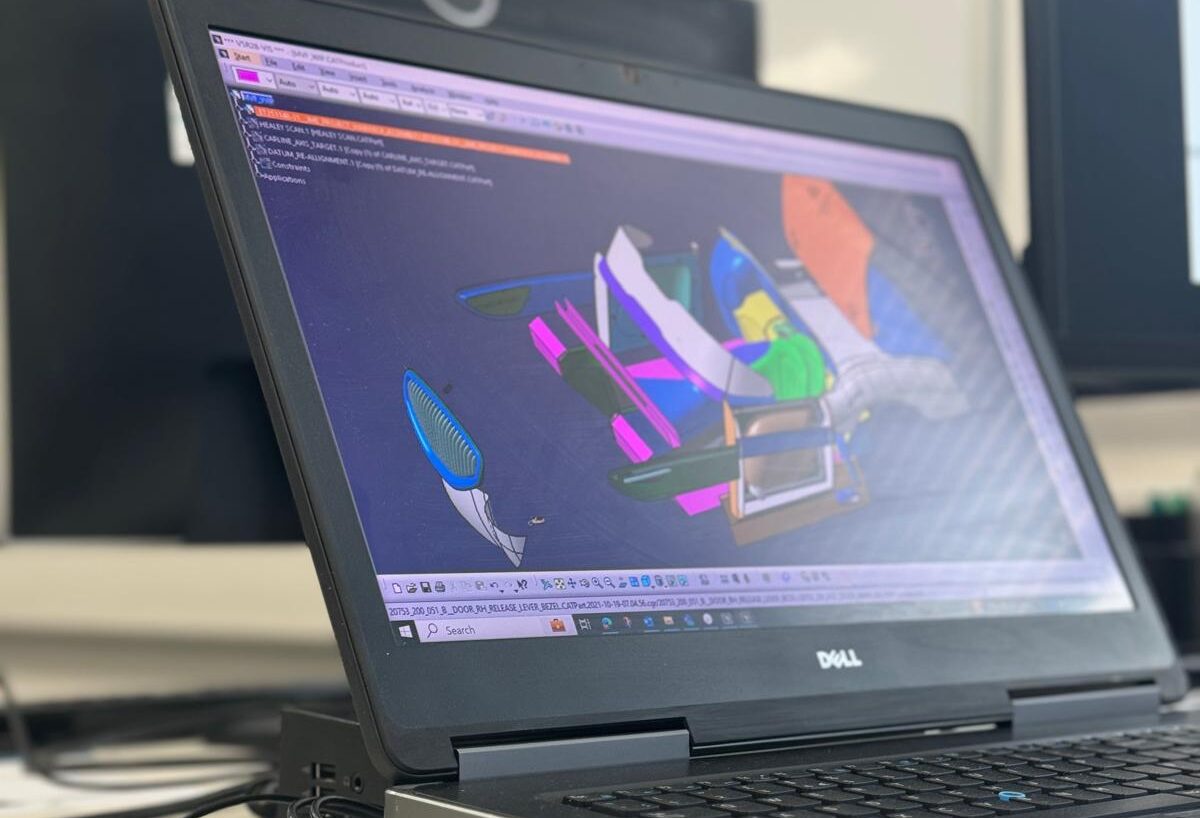

Computer Aided Design is used to create, modify, analyse, and optimise designs. It makes the design process more efficient, allows for effective collaboration, and for the testing and iteration of designs before manufacture, saving time and money, while also ensuring high levels of precision and quality.

The CAD Team

We have a full CAD team that is the epitome of design excellence, with over 250 years of combined experience. Their extensive expertise ensures that every project they work on is carried out with the highest levels of precision. They are excellent at navigating complex designs and consistently meet the high standards our clients expect.

CAD’s Role within Envisage

The CAD team’s role is the starting point for any project within Envisage. They provide support on models and tooling, aligning client designs with our in-house capabilities. The team take designs and liaise with everyone from modellers in the build studios and the trim studio, to paint technologies and electronic research and development. CAD ensures everyone working on projects are on the same page, helping to turn a full design into a working concept.

Supporting Our Clients

When data is received from the customer, CAD works to align their vision with Envisage’s capabilities; creating ways to make the design come to life and adapting to the specific requests from the client. Regular meetings are held, as often as necessary, to review designs and progress, ensuring that project requirements and client expectations are met.

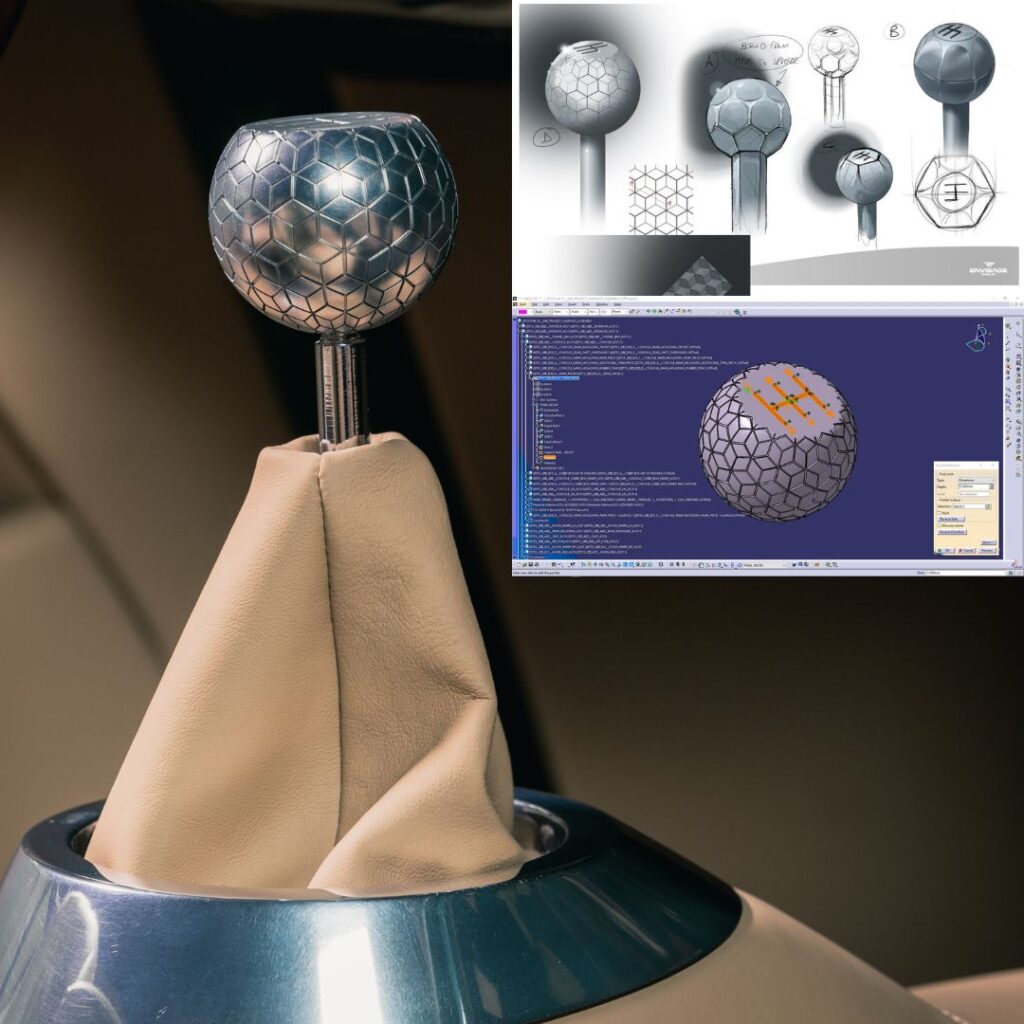

Case Study: Healey By Caton

Elements of the Healey by Caton were developed by CAD to ensure they would work. The key fob for example, was built in CAD to make sure the exterior buttons and shape would work with what electronics research and development had created to go inside.

On the steering wheel, a unique indicator was designed, and the team ensured the functionality of this component. The horn pad was also reverse engineered in CAD to fit the Caton badge. The centre console was modelled in CAD, the door hinges were checked for fit and functionality, and the car door latch was re-engineered to work with the design.

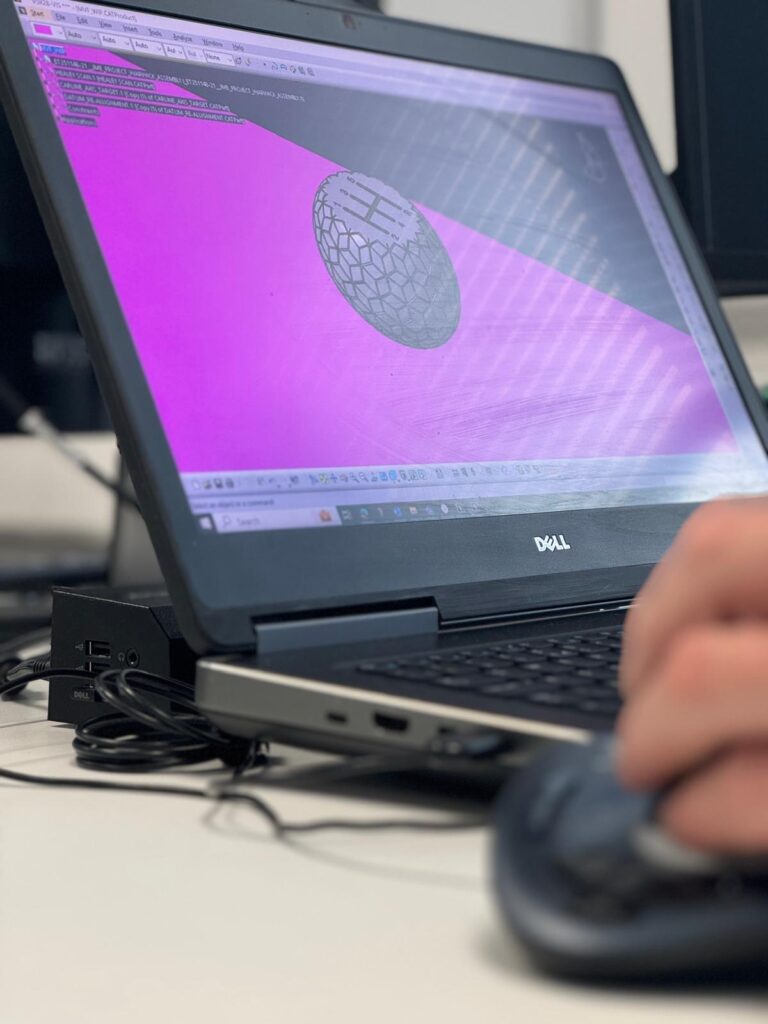

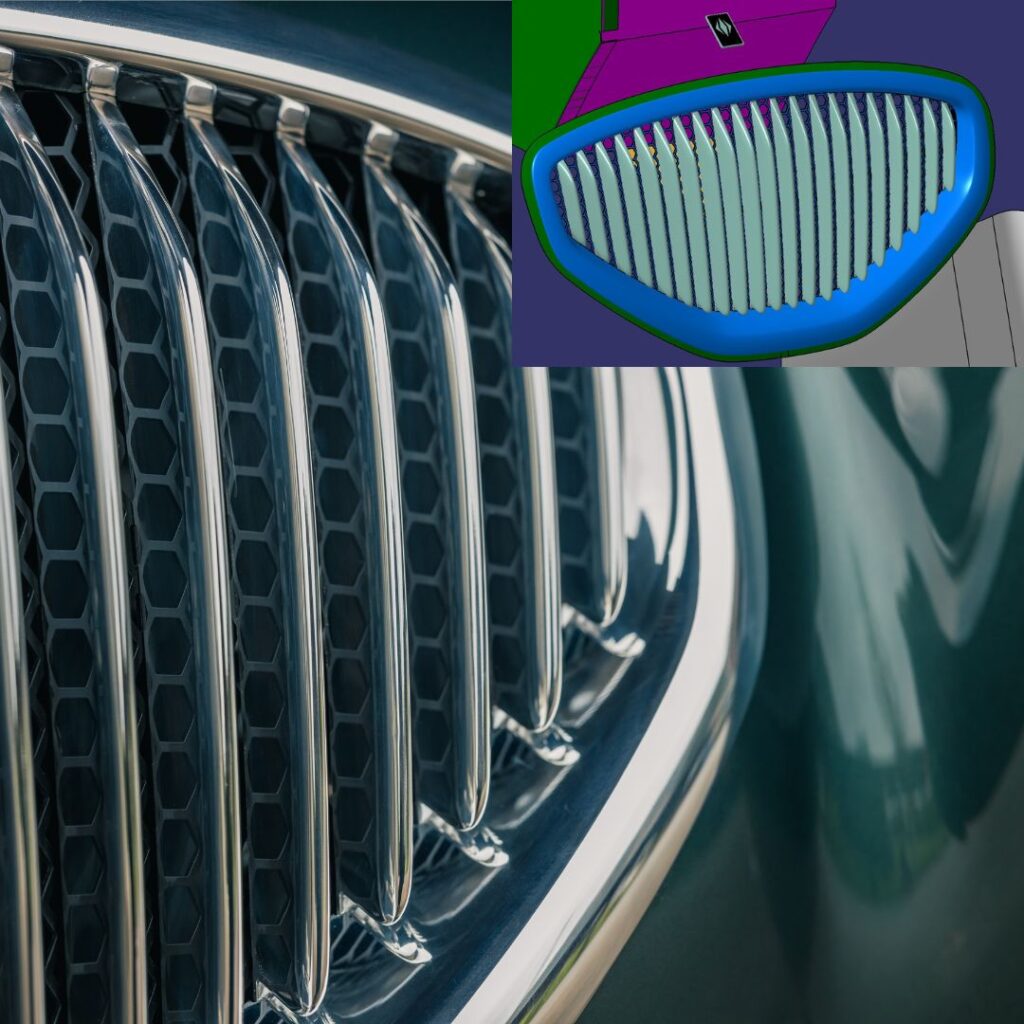

The Caton hexagonal trim flows throughout the entire vehicle from the gear shift and its surround; to the side vents and front grille. The CAD team transformed sketches and visualisations of these elements into functional, real-world designs. The idea for the front grille was to create a floating look. CAD ensured the veins aligned with the hexagonal trim behind, making the vision tangible.

This car shows how the CAD team would be able to support with the creation and application of any pattern within any project, not just supporting technical elements but also brand aesthetics.

Case Study: 7X Design Rayo

Our team collaborated with 7X Design to achieve the concept of the 7X Design Rayo which has been created to achieve a 300mph record of the fastest coach built car. We were tasked with making the new shape of the car fit, after being supplied with the A-surface data and hand-scanning the base vehicle to produce a 3D design. We matched the design to sub-millimetre accuracy and helped ensure the design was robust.

Following this initial work, the car came back for upgrades to its aerodynamics. The CAD team worked with 7X Design on additions to the car to increase the downforce. At the front of the car, canards were added, larger winglets were added to the back of the car which had more flip.

Model making Expertise across Industries

Our experience is not just limited to the automotive industry. Envisage have the experience and capabilities to support almost any type of model within any sector. This includes but is not limited to aerospace, transportation (such as motorcycles, rail, and marine), and bespoke products.

For more about our CAD team follow this link.

For more information about how Envisage can help bring your project to life, contact us.