As part of the Envisage Year of Innovation, our CMF team has undertaken research and development to transform waste materials Envisage creates into something that has a practical application. The purpose of the project was to inspire conversation about how materials can be used after end of life and reduce waste.

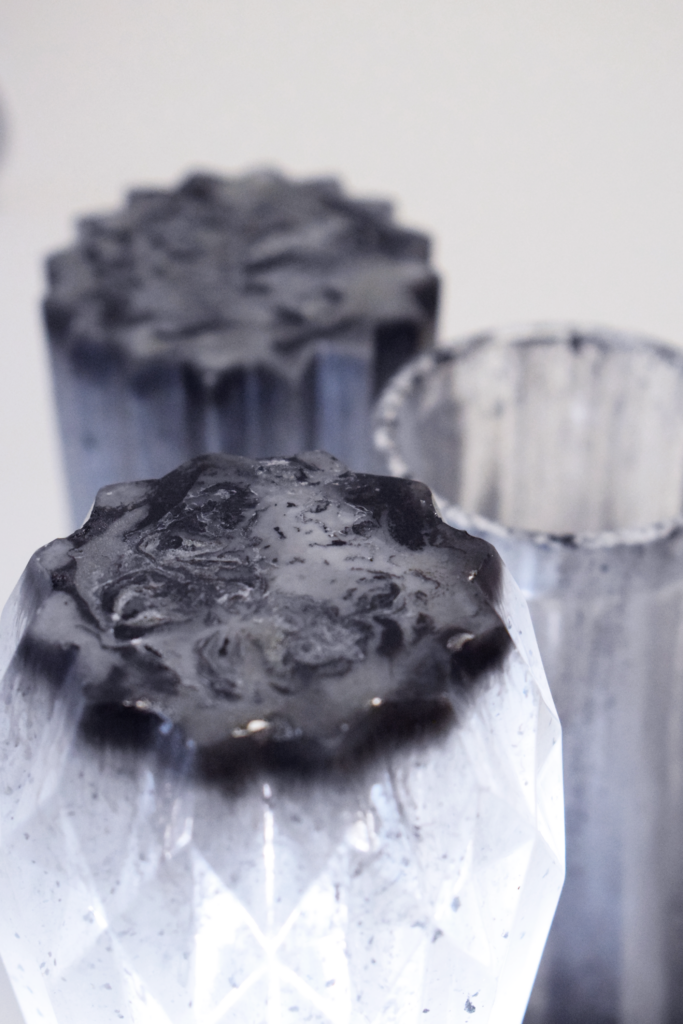

Material Development 01: Waste Paint x Bio-Resin

Using waste paint that either won’t be used or has expired, the CMF team created decorative surfaces by mixing the paint with bio-resin. This exercise showed that a multitude of variations can be achieved with different patterns, techniques, colour ways, shapes, and forms. This material could have multiple uses, including lighting, sculptures, and hard a-surfaces within a vehicle.

The team used three techniques, first, layering clear resin with layers of paint which created a dimensional effect. The second technique was mixing the paint with the resin to create a ceramic effect on one side and a melted metal effect on the other. Finally, mixing alcohol to thin the paint and dripping it onto partially dried resin, creating a marbled effect on the top and a splatter effect at the bottom. This material is unique because every outcome is different, creating something that is bespoke every time.

To further develop this material, the CMF team will experiment with more techniques, colours, and forms, along with machining it to investigate further applications.

Material Development 02: Leather Foam

This development explores how leather offcuts can be reused and repurposed, as opposed to going to a landfill. A bio-based foam was created integrating leather waste from Envisage’s in-house Trim Studio with aerated natural latex, transforming something mundane into a piece for conversation. The purpose of this material is to open discussions about alternative foams and their applications in seating and insulation. This material was developed by combining finely shredded leather with a bicarbonate of soda and latex and then layering this mixture with vinegar to evenly distribute air bubbles. The CMF team are investigating a collaboration with a sustainable foam company to further develop this material and investigate other ways of utilising waste leather in other products.

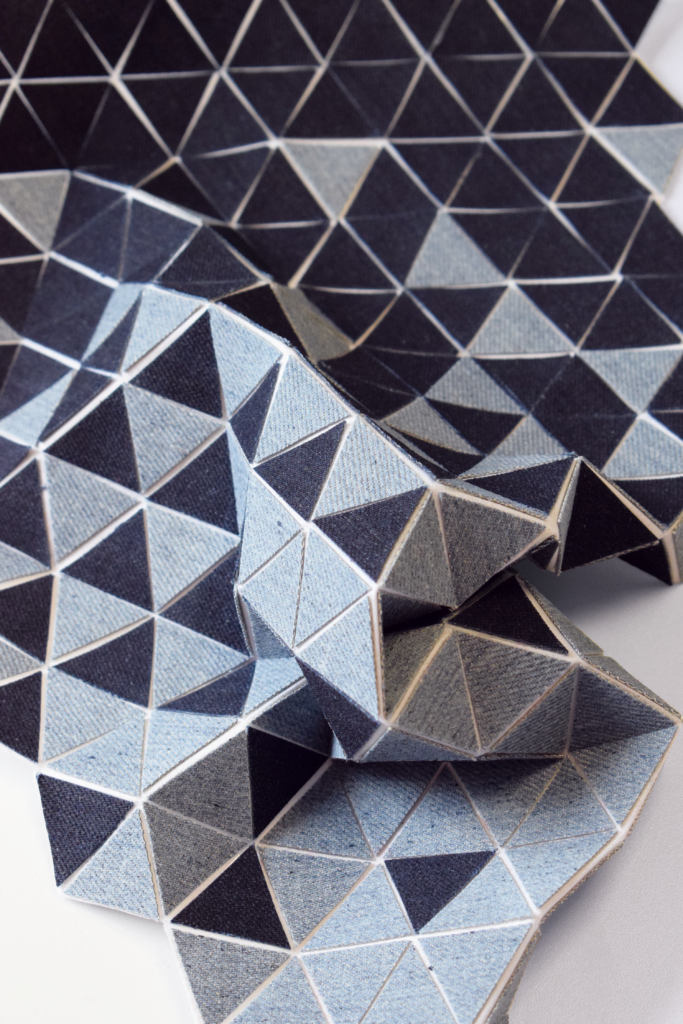

Material Development 03: Denim Marquetry

Showing how leftover materials can be repurposed, this development uses denim from a past client project. A veneer was made from stiffened denim pieces and assembled into a pattern that can be used on any decorative surface or hard a-surfaces within a vehicle that would have previously been a veneer. It can also be folded and manipulated for applications on rounded and shaped surfaces.

To create this development, denim was stiffened, cut into shapes, and bonded to a fabric backing. It combines traditional techniques with innovative materials and, being handcrafted and bespoke, offers lots of opportunities for customisation of patterns and material choices.

Material Development 04: Your Next Project

Envisage’s CMF team have the capabilities to explore, research, and develop unique and innovative materials for application within almost any vehicle or product. These material developments are available to use within your next project. For more information regarding how these can be incorporated, or for research to develop a material completely unique to you, contact Hollie now (hrutter@envisagegroupltd.com).