A Seat for Technical Demonstration

Posted November 14, 2023

Collaboration between the different departments at Envisage is central to almost every project. The technical demonstrator is a collaboration between Electronic Research and Development and our in-house Trim Studio. This is through the making of a seat that has the ability to move autonomously exhibiting the skill of our electrical engineers, and trimmed with different styles, showing the skill of our trim specialists.

Electronic Research & Development

A key feature of the technical demonstrator is its ability to move autonomously between being fully upright to fully reclined. The seat is controlled by a single body control module (BCM) and the motors are directly connected to the BCM’s on board relays, which are wired into a H Bridge configuration, allowing each motor to be driven in two directions.

To make the seat move independently, a current sensor device was installed in line with each motor, with a timer operating on the BCM, keeping the seat in its position for a number of seconds before initiating the other function (either recline or upright).

On systems where exact, repeatable positions are required every time (for example, on modern seats which have multiple presets for different users, not necessarily fully reclined or upright), additional techniques can be used to track the seat’s position, such as installing encoders on the motor shafts to track rotation, all of which are capabilities offered by Envisage’s Electronic Development.

Trim Studio

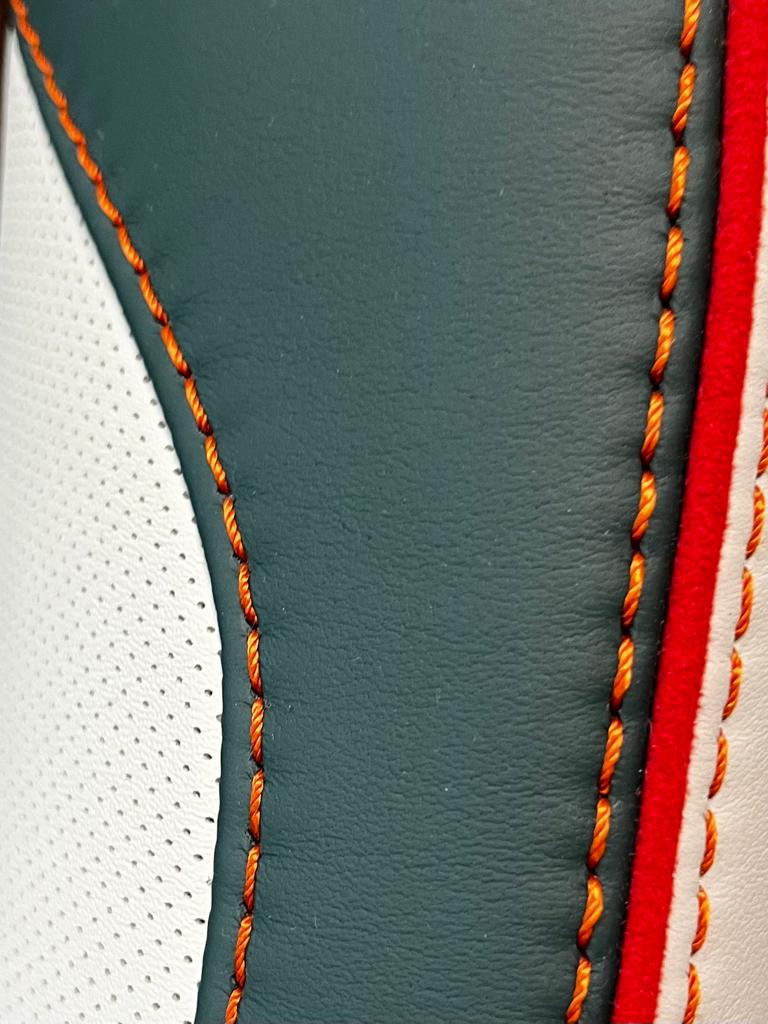

This seat not only demonstrates the capabilities of our Electronic Development department, but also the skill of our in-house Trim Studio. Our trim specialists used mostly leather, with tartan fabric, PU ultra fabric and perforated leather panels to show how different materials can look and be joined together. The stitching truly highlights the abilities of the trim studio, from diamond quilting and twin needle stitching using Durkopp Adler sewing machines to Alcantara micro-piping.

With a high level of skill and experience, the capabilities of the trim studio are not limited to the designs exhibited on the technical demonstrator. Very few companies have a trim shop as an in-house service offering design support and pattern development among other services; the capabilities of Envisage’s trim team can meet almost any brief.

For more information on how we can help you with your next project, press here for the Trim Studio, or press here for Electronic Research and Development.