Combining the essence of tradition with innovation, preserves automotive heritage and love of classic cars. Envisage Metal Forming and Classic Restoration are experts when it comes to meeting our clients’ briefs, whether that is restoring a car to its original state, reimagining it for modern context, or something completely bespoke.

Traditional Skillsets

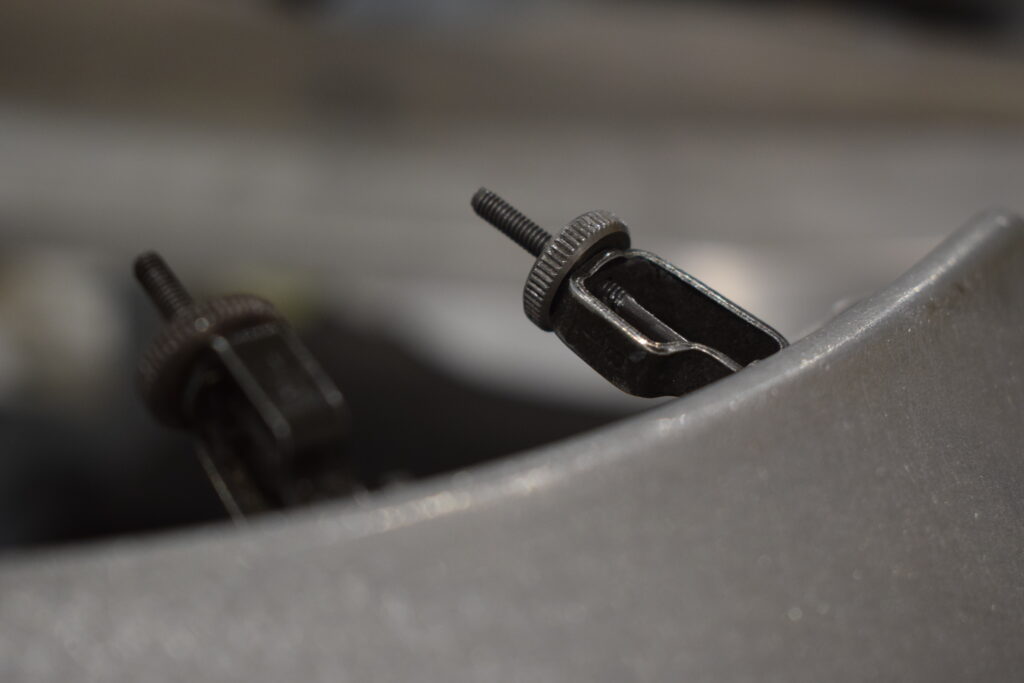

Our metal forming team define what craftsmanship is, using traditional techniques including English Wheel, hammer forming, and welding to fabricate new panels and repair vehicle damage due to age. These skills allow our metal-formers to achieve the precise lines, curves, and details that we love on our classics and retro vehicles. Combining these traditional skills with new technologies and innovation, Envisage are well placed to produce restorations that are true to their heritage, but built for today.

Preserving Vehicle Heritage

As one of the leading vehicle restoration companies, we are trusted by OEM’s, start-ups, and vehicle owners to carry out their restorations to the highest quality. We collaborate closely with our them to ensure we fully understand their needs as we work to turn their ideas into a reality and they are confident that the solutions we offer will preserve their vehicles heritage.

Bespoke Projects

Utilising a wealth of in-house capabilities, we can create almost anything. Our metal forming team collaborate with other departments to bring ideas to fruition. From the selection of colour and materials with CMF Design, or the creation of beautiful bespoke paints with Paint Technologies; to specialist trim with the Trim studio, and unique lighting sequences with Electronic Research & Development. Combined with the artisan skills of the Metal-Forming team, we can create beautiful, aluminium furniture, sculptures and art installations or ornate staircases, the possibilities are endless.

CASE STUDY – Mk1 Ford Transit

Envisage was approached by eBay, to design, restore, and convert a one-off Mk Ford Transit. The Team restored the vehicle, carrying out necessary repairs needed due to the vehicle’s age. It was completely stripped removing everything from the seats and under the dash to smaller parts such as the window wipers. In addition, our skilled metal-forming team fabricated a new panel replacing the old damaged rear valance and repaired patches of rust in the floor.

CASE STUDY – Austin Healey 100-6

The metal-finished, raw aluminium body truly emphasises our Metal Forming teams artistry. A range of traditional techniques were used including English wheel, hammer forming, and welding. The car was restored using the original shrouds, boot and bonnet, and door inners, accompanied by new fenders that were made by hand.

CASE STUDY – Model 01: The Couch

The rear fenders that make this bespoke couch were made from flat aluminium rolled together with the seat back, the rear balance, and metal finished wings. Made using traditional methods, such as welding, hammer and hand weight, the Couch is completely crafted by hand, creating a thing of beauty of the highest quality.

For more information on how we can support your next restoration project, or to commission a piece of artwork, please contact Andy (ahunter@envisagegroupltd.com)